IAQ Products

Fume Purification System

Features

- Up to 95% treatment efficiency, conform to the GB18483-2001 Standard

- Completely decompose the organic in the fume, different from the collecting of lampblack and do not produce secondary pollution

- Accompany Sterilizing effect

- No residue water and oil and no sound and irritation pollution

- Low wind drag and consume less power

- Not need water or cleanser, small footprint and synchronous operation with exhaust system

- No large machinery, no need professional serviceman

- Low fire risk

Suitable Venue

- Restaurants

- Hotels

- Entertainment Venues

- Supermarkets

- Canteens

- Food Processing Factory

- Hospital

- Sanatorium

- Education Institution

- Office Buildings

- Malls

Purification Operational Procedures

- The cooking fume is initially inhaled by exhaust system and enter the Fume Purification System (TEMCO)

- Oil, smoke and odor can be degraded with sterilization effect

- Generate non-toxic, odorless, stable molecules and discharge without pollution

- Small amount of white powder may generate at the bottom of the purification apparatus, regularly collection is needed (The white powder is non-poisonous, harmless, odorless, non-flammable and can be biodegraded)

Technical Description

When the cooking fume goes into the photochemical treatment apparatus, the generated UV light radiated on the gas and smoke, which causes the rupture of C-C bonds of saturated hydrocarbons, thus the molecular structure changes and forms the stable CO2 and H2O. At the same time, the oxygen molecules generate excited and active Oxygen Free Radicals (OFR) through the photo radiation. And the excited Oxygen Free Radicals (OFR) contact with O2 and H2O to generate the strong oxidizing Ozone (O3) and Hydroxyl radicals (•OH). Since Ozone (O3) and Hydroxyl radicals (•OH) possess high oxidation potential with 2.07V and 2.8V respectively (The oxidation potential of Oxygen (O2) is 1.22V), they are able to oxidize and decompose almost all the organics. The smoke and odor will transform to non-toxic water (H2O), Carbon dioxide (CO2), Oxygen (O2), Solid Organic Polymer and Inorganic Salt (white powder). The total removal rate of oil, smoke and odor can be over 95%.

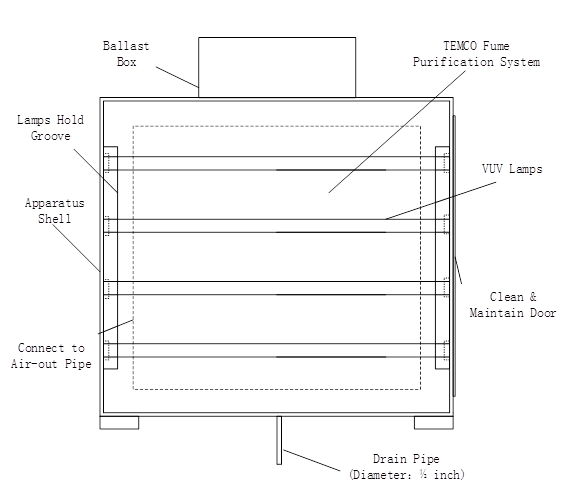

Figure.1 The sketch and layout drawing of fume purification apparatus (TEMCO) (The direction of arrows indicate the direction of smoke flow)

Figure.2 Cross-section drawing of fume purification apparatus (TEMCO), the cutting position is dotted line shown in Figure.1 (The direction of smoke flow is from outside paper to inside paper)

Components of Fume Purification apparatus

- VUV Lamps: The most critical component of the whole apparatus. Used to degrade the contaminants and purify the air by the light irritation. The high quality VUV lamps are customized to deal with the cooking smoke, and are manufactured and assembled by advanced technologies. We make sure that the lamps working with high efficiency and can be continuous used for a long time

- Ballast: Support the work of VUV lamps. Our high quality ballast ensure the long-term operation of the purification system

- Apparatus Shell: We select the 20 gauge (1mm) thick S/S 304 stainless steel, to guarantee the safety of UV radiation. In the meantime, it can help avoid the common photo-generated electrons, thus make it safe to user

- Drain Pipe: Located at the bottom center, its diameter is 1/2 inch. It is used to discharge the water produced by the chemical reaction and coming along with the hot smoke to assure the smooth running of the system

- Flow Baffles (Optional): According to the different smoke flow rate and velocity, it is optional to install the flow baffles in front of the VUV lamps. The baffles could protect the stability of the lamps and help to disperse the inflows in order to improve the treatment efficiency

- Clean & Maintain Door: This door is designed for the routine cleaning work of the inner apparatus and VUV lamps, and also the easy conduction of maintaining works. It make possible to carry on the cleaning and lamp replacement work for non-professional personnel with the Clean & Maintain Door

- Exhaust System: Used to collect the smoke produced during cooking or food processing. It is unnecessary to remold or upgrade the existing exhaust system when installed the Fume Purification Apparatus (TEMCO), because of the low wind drag and the high flexibility

- Gas Duct: Control the direction of the collected smoke flow. Generally, when installing the Fume Purification Apparatus (TEMCO) to an existing cooking fume treatment system, we only need refit the gas duct where the TEMCO system installed

FOR ADDITIONAL INFORMATION, contact us for complete solutions and an opportunity to let TEMCO Technologies serve you with professional expertise.